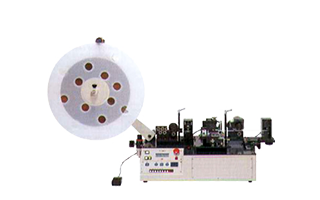

| Lead frame attachment machine | FI-930T type use |

|---|

| Lead frame standard size cut length | MAX 280mm |

|---|

| An application lead frame size and a substrate size | W:65mm or less

D:40mm or less

L1:8~20mm

L2:55mm or less

T:0.6~8mm

(It is clamper exchange when T is 9?13 mm.) A clamper is an option. |

|---|

| The direction of a work flow | The left -> right

|

|---|

| Work conveyance | Belt conveyance -> mechanism zipper system |

|---|

| Flux application | Dip system (sub tub up-and-down system) |

|---|

| Preheating system | Far-infrared heater(0~200℃) |

|---|

| Soldering system | About 12 seconds (it contains for about 3 seconds solder immersion time) |

|---|

| Baton time | About 12 seconds (it contains for about 3 seconds solder immersion time) |

|---|

| Dip system | An arbitrary setup in key operation is possible till 0 to 9.9 seconds. |

|---|

| Solder surface dregs removal | Each time, it is based on a scraper. |

|---|

| Solder icicle removal | It is based on a ceramic heater. |

|---|

| Work recovery | it is based on an exclusive career -- dropping |

|---|

| Memory function | 50 kinds (they are an arbitrary setup and liquid crystal display by key operation, such as the amount of soldering up-and-down movements, immersion time, and up-and-down speed) |

|---|

| Power supply | 200V (single phase), 50/60 Hz, 30A |

|---|

| Common sky pressure | Dry air 5kg/c㎡ Air pressure display (panel side) |

|---|

| Outside dimension | L abbreviation 1,910 x W 985 x H 1,390mm |

|---|

| Weight | About 250 kg |

|---|

| Solder tub capacity | About 20 kg |

|---|

| Painting color | ECG standard color (2.5V7.6/1.4 leather color) |

|---|